耐磨陶瓷材料企业

提供合理化防磨解决方案

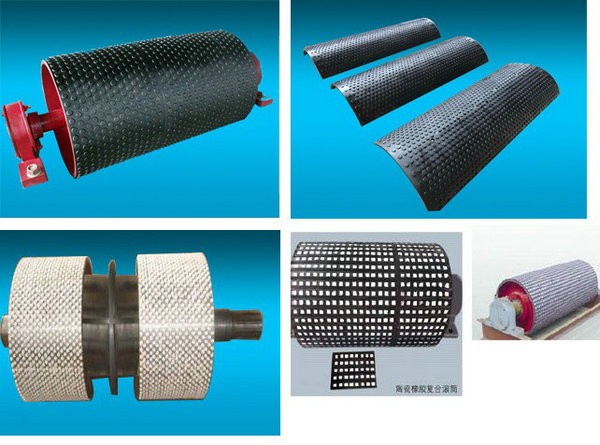

SK wear-resistant rollers are the current domestic low-cost, cost-effective roller belt conveyor rollers and idlers are the core spare parts of the system, due to the defects of the roller overcoating, resulting in degumming, slipping, and wear-out. It directly causes a significant increase in labor intensity and maintenance costs of workers, and a reduction in production efficiency. Seriously, it will also cause production safety and quality accidents.

There are usually problems: The belt conveyor rollers are degummed, slipped, and worn!

The belt roller bearing is stuck and fails, and the tube skin is worn!

Common solutions:

First, the use of vulcanized rubber to increase friction and wear resistance (rubber is not wear-resistant, need to be over-coated)

Second, the method of sticking or vulcanizing ceramic sheets is used to increase the wear resistance of the drum (belt tension and friction on the surface of the drum will form a strong peeling force. The peeling force can easily tear the ceramic sheet from the rubber, and the actual service life Not long, it also needs to be encapsulated repeatedly).

联系人:杨经理186-7821-9881

联系人:陈经理133-7533-9393

电话:0533-2688588传真:0533-2688588

邮箱:zb_yujie@163.com

地址:山东省淄博高新区金晶大道267号颐和大厦

华体会登录首页 专注电子游戏尽在华体会 、华体会直播 、氧化铝研磨球生产研发,厂家直销,价格优惠,欢迎来电咨询。